Breadcrumb

- Home

- Melbourne Stories

- Recycled Plastic Paving the Way, The Enviromesh Solution

Recycled Plastic Paving the Way, The Enviromesh Solution

About

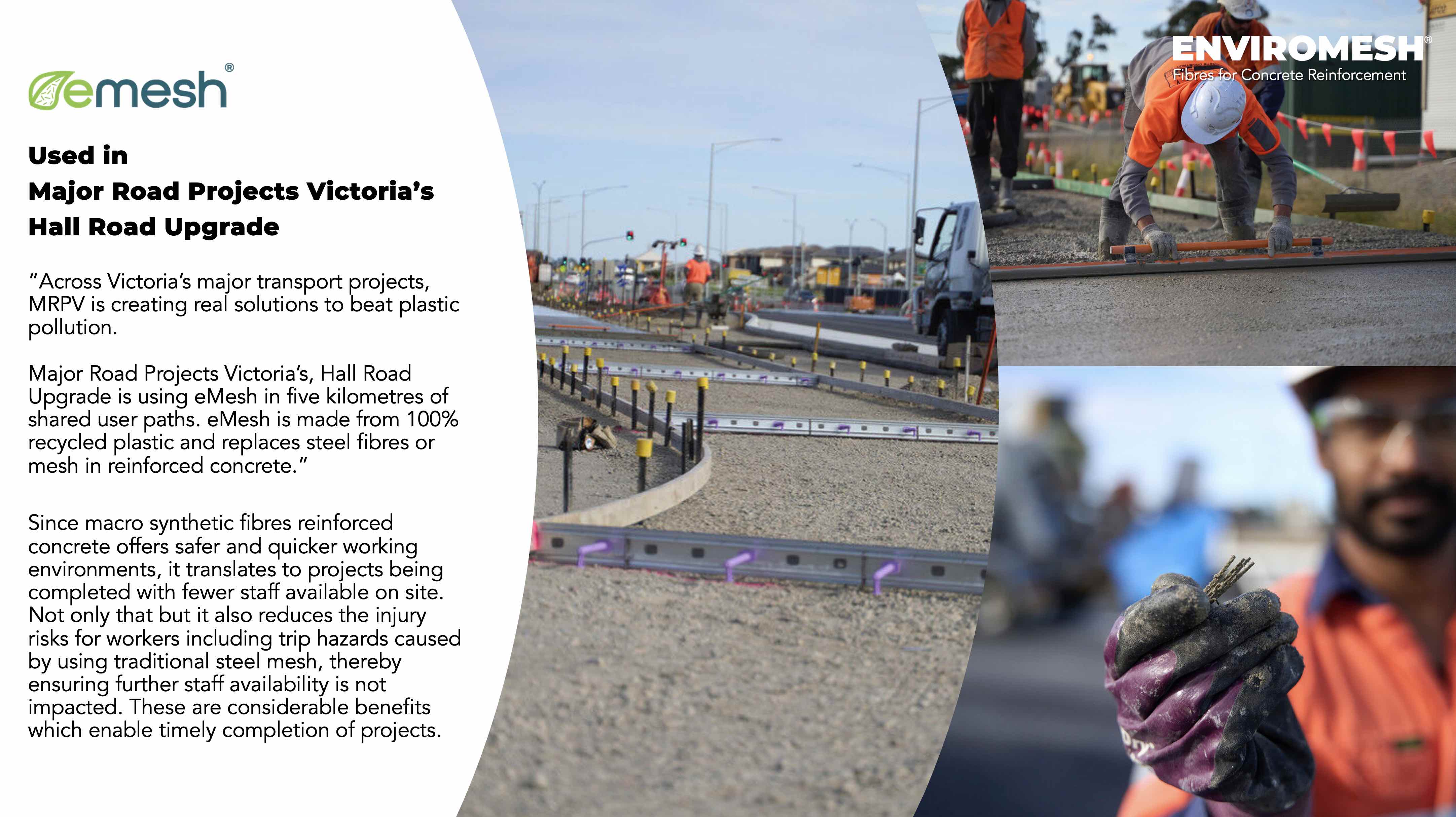

Enviromesh is the leading provider of synthetic fibres made from both 100% recycled plastic and sustainable virgin materials. Our fibre solutions replace steel mesh in concrete and are used in a wide array of construction projects ranging from large infrastructure projects for state governments and local councils to specific solutions for maritime, coastal, mining, precast industrial and warehousing projects.

We provide comprehensive end to end fibre reinforced concrete solutions through design and engineering support led by a team of concrete, fibre, and engineering experts. Our reliable feed stock and local manufacturers support our vast supply network and enable worldwide delivery.

We supply for Australia wide projects including infrastructure projects for remote island communities like the Palm Islands, as well as for projects in New Zealand and the Pacific Island Nations.

With more than 30 years in the business, we are committed to sustainability and innovation and align our operations with the United Nations Sustainable Development Goals (UN SDGs)

to create a positive impact on the environment, community, and industry. Additionally, our dedication to social responsibility extends to inclusive workforce practices and philanthropic initiatives, setting us apart as a socially conscious organisation.

Enviromesh prioritises environmental responsibility and solutions, and helps reduce the carbon footprint of concrete construction. Our focus is on reducing waste and minimising the carbon footprint associated with the built environment.

Enviromesh eMesh fibres are made from 100% recycled plastic; by replacing steel mesh they can reduce CO2 emissions by up to 94%.

Why Melbourne

Enviromesh is focussed on promoting and scaling our business not only in Melbourne but wherever we can because we want to be part of the solution, to ensure infrastructure development is environmentally friendly. Our vast supply chain and warehouse network enables us to meet the demand for our products anywhere in Australia.

We have several key reasons to expand in Melbourne that are a result of our commitment to environmental sustainability and the ability of our fibre solutions to reduce carbon emissions in infrastructure development.

Our commitment to Environmental Sustainability is reflected in our solutions.

Enviromesh Fibres specialise in producing sustainable fibre solutions that are designed to minimise environmental impact. We upcycle waste plastic to produce eMesh fibres that are made from 100% recycled plastic. By replacing steel mesh, they can reduce CO2 emissions by up to 94% and deliver innovative reinforced concrete. This directly contributes to reducing waste and promoting a circular economy.

We also use sustainable virgin materials to manufacture micro and macro synthetic fibres for concrete reinforcement that replace steel fibres and steel reinforcing mesh.

Our virgin synthetic fibres are engineered to require less energy and up to 94% less water during production compared to traditional materials like steel, thereby lowering their carbon footprint by up to 60%. This aligns with Melbourne's growing emphasis on sustainability and green initiatives, especially for Victoria’s Big Build projects.

Victoria and Melbourne are known for their progressive stance on green building and sustainable urban development. Enviromesh Fibres' products are well-suited to meet the city's stringent environmental standards and can contribute to LEED and other green building certifications. Our fibres are extensively used in Victorian Infrastructure projects such as NWPA Bell to Moreland Level Crossing Removal project.

Melbourne's government and local authorities are highly supportive of sustainable business practices. Policies and incentives aimed at reducing carbon emissions and promoting green technologies provide a conducive environment for Enviromesh Fibres to thrive.

There is a growing demand for sustainable construction materials. Developers and builders are actively seeking eco-friendly alternatives to meet consumer preferences and regulatory requirements.Enviromesh Fibres see potential to leverage these advantages to drive their mission of promoting environmental sustainability and reducing carbon emissions in infrastructure development. Finally, and most importantly, we intend to promote our fibres with a sole focus on achieving better environmental outcomes through our sustainable products and engineering support.

Challenge

At the Climate Talks COP27, the 2022 Global Status Report for Buildings and Construction finds that the sector accounted for over 34 per cent of energy demand and around 37 per cent of energy and process-related CO2 emissions in 2021.

Raw resource use is predicted to double by 2060 – with steel, concrete and cement already major contributors to greenhouse gas emissions. Materials used in the construction of buildings already account for around nine per cent of overall energy-related CO2 emissions.

Globally and locally, the increasing CO2 emissions are a challenge for the environment and society.

Solution

Enviromesh offers sustainable fibre reinforced concrete solutions to replace steel mesh in construction. By replacing steel mesh, we help in reducing carbon emissions, cost and time of building and construction projects. Our solutions also increase productivity, on-site safety, and performance by eliminating issues like steel corrosion and reducing cracks in concrete. This means less ongoing maintenance and durability.

To replace steel mesh in concrete we provide below products and services:

- Steel Mesh Alternatives

- Fibres made from 100% Recycled Plastic

- Virgin Macro and Micro Synthetic Fibres

- Concrete Mix Design Consultation

- Engineering and Design Support

Some of the key customer and environmental problems that we are addressing are:

- Waste plastic is diverted from landfill and used as concrete reinforcement

- Co2 emissions are reduced by up to 94%

- Up to 94% water saved in manufacturing process

- Substantial reduction in fossil fuel consumption required for transportation of material

- Cost savings from easy transportation and storage of fibres

- Cost savings from less labour-intensive process of using fibre reinforced concrete on site

- Cost saving from reduced engineering inspection and equipment needs

- Reduced health and safety hazards as the need of transporting, handling, laying, cutting, and tying steel is eliminated

- Increased concrete asset life due to elimination of steel mesh corrosion issues

- Concrete assets require less repair and maintenance

Result

Enviromesh has steadily grown in sales, increasing its manufacturing and delivery capability as its solutions and services have gained market traction.

One of our key achievements is that we have used 1000 tonnes of recycled plastic – equivalent to plastic waste produced by 6,400 Australians in a year. We have provided around 44,000 hours of work to NDIS supported workers who package our sustainable fibres. - Alex Lester, CEO

The benefits of replacing steel mesh in concrete also translates to other environmental savings:

- eMesh has resulted in reduction of 22,000 tonnes of emissions. Equivalent to removing 4,800 cars from roads for 1 year.

- Saved 4,400 tonnes of fossil fuels

- Saved 348,000 cubic metres of water – equivalent to 139 Olympic sized swimming pools.

Our business model has already upscaled, and is designed to expand through supply contracts and agreements that are already in place. We manufacture in two states, and distribute our fibres to all states in Australia, using 8 contracted freight and storge providers. This is achieved through 9 storage points along the east coast, from Melbourne to Cairns to ensure we have a timely delivery regardless of the customers location.

Internationally, we win supply agreements and can deliver anywhere in the world within 4 weeks. Our top 3 countries that we supply to outside Australia are New Zealand, Timor and Vanuatu.